Zdrowie jest najważniejsze

The laser cleaning process involves focusing a laser beam onto the surface of the material to be cleaned. The energy from the laser beam vaporizes the contaminants, leaving behind a clean surface. This method is non-abrasive and does not damage the underlying material, making it ideal for delicate surfaces.

There are many benefits to using laser cleaning technology. Some of the key advantages include:

| Advantages | Description |

|---|---|

| Non-abrasive | Laser cleaning does not damage the underlying material. |

| Environmentally friendly | Does not require the use of chemicals or solvents. |

| Highly precise | Can target specific areas without affecting surrounding areas. |

| Efficient | Removes contaminants quickly and effectively. |

Laser cleaning technology is used in a wide range of industries for various applications. Some common uses include:

| Industry | Application |

|---|---|

| Automotive | Removing paint and rust from car bodies. |

| Aerospace | Cleaning turbine blades and engine components. |

| Electronics | Removing solder and flux residues from circuit boards. |

Laser cleaning technology is a versatile and efficient method of removing contaminants from surfaces. Its non-abrasive nature and precision make it an ideal choice for industries looking to improve their cleaning processes.

#laser #cleaning #technology #industrial #applications

słowa kluczowe: laser, cleaning, technology, surface, contaminants, efficient, non-abrasive, precise, applications, industrial

frazy kluczowe: laser cleaning technology benefits, laser cleaning applications in aerospace, laser cleaning technology in automotive industry, laser cleaning technology for electronics, advantages of laser cleaning technology.

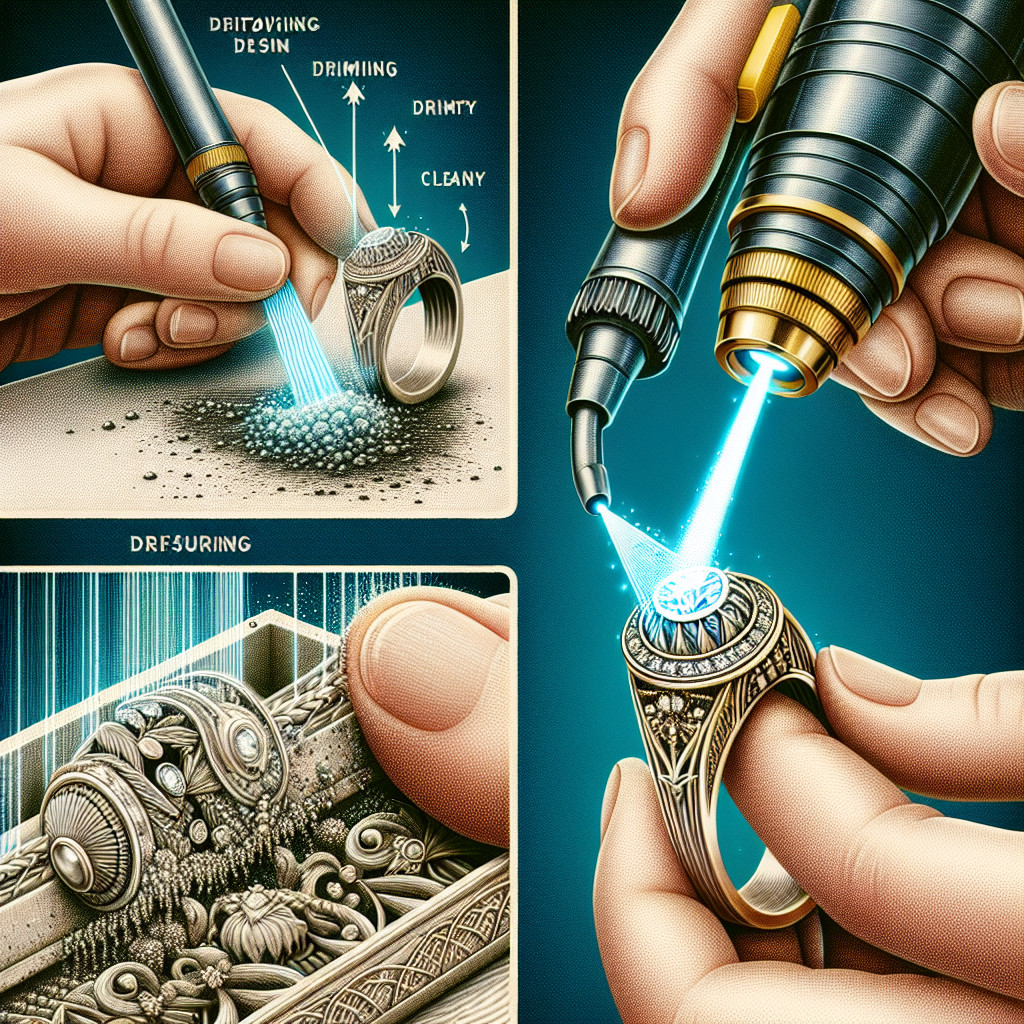

The evolution of laser cleaning in the jewelry industry can be traced back to its origins in industrial applications. Initially used for cleaning metal surfaces in manufacturing plants, the technology was quickly adapted for use in the jewelry industry due to its precision and efficiency. Today, laser cleaning machines are a common sight in jewelry workshops around the world, offering a safe and effective way to clean delicate pieces without causing damage.

Some key milestones in the history of laser cleaning in the jewelry industry include:

– Introduction of laser cleaning technology in jewelry workshops

– Development of specialized laser cleaning machines for different types of jewelry

– Integration of laser cleaning into traditional jewelry cleaning processes

– Adoption of laser cleaning by high-end jewelry brands for restoration and maintenance

🔹 Laser cleaning has become a preferred method for removing tarnish and oxidation from silver, gold, and platinum jewelry without the need for harsh chemicals or abrasive techniques. The laser beam targets the surface of the metal, vaporizing contaminants and leaving behind a clean, polished finish.

🔹 Gemstones such as diamonds, sapphires, and emeralds can also benefit from laser cleaning, as the technology is gentle enough to remove dirt and debris without damaging the stone. Laser cleaning is particularly useful for removing dirt from hard-to-reach areas of intricate jewelry designs.

🔹 The use of laser cleaning in the jewelry industry has not only improved the efficiency of cleaning processes but has also enhanced the overall quality of finished pieces. Jewelers can now offer their customers a higher level of service by using laser cleaning to restore old or damaged jewelry to its original beauty.

In conclusion, the history of laser cleaning in the jewelry industry is a testament to the constant innovation and advancement of technology in the field. From its humble beginnings in industrial applications to its widespread adoption by jewelers worldwide, laser cleaning has become an indispensable tool for maintaining the beauty and value of precious jewelry pieces.

#laser #cleaning #jewelry #industry

long-tail phrases: laser cleaning technology in jewelry, evolution of laser cleaning in jewelry industry, benefits of laser cleaning for gemstones.

Overall, laser cleaning is a versatile and efficient method for removing a wide range of contaminants from surfaces. Whether you need to remove rust, paint, oil, or any other type of contaminant, laser cleaning can provide a fast and effective solution.

Hashtags: #laser #cleaning #contaminants #rust #paint #oil #grease #corrosion #scale #adhesives

Keywords: laser cleaning, contaminants, rust, paint, oil, grease, corrosion, scale, adhesives

Long-tail phrases: types of contaminants removed by laser cleaning, benefits of laser cleaning, applications of laser cleaning

While the initial cost of purchasing a laser cleaning machine may be higher than traditional cleaning methods, the long-term cost savings can outweigh the initial investment. Laser cleaning requires less labor and materials, resulting in lower overall costs for jewelry cleaning.

Traditional cleaning methods such as ultrasonic cleaning or chemical cleaning can be time-consuming and may require multiple steps to achieve the desired results. Laser cleaning, on the other hand, is a one-step process that can be completed quickly and efficiently.

Overall, laser cleaning is a cost-effective and efficient method for cleaning and restoring jewelry. While the initial investment may be higher, the long-term cost savings and benefits make it a worthwhile investment for jewelry businesses.

#jewelry #laser #cleaning #costeffectiveness #efficiency #precision #environmentallyfriendly

#costsavings #traditionalmethods #ultrasoniccleaning #chemicalcleaning #investment #jewelrybusinesses

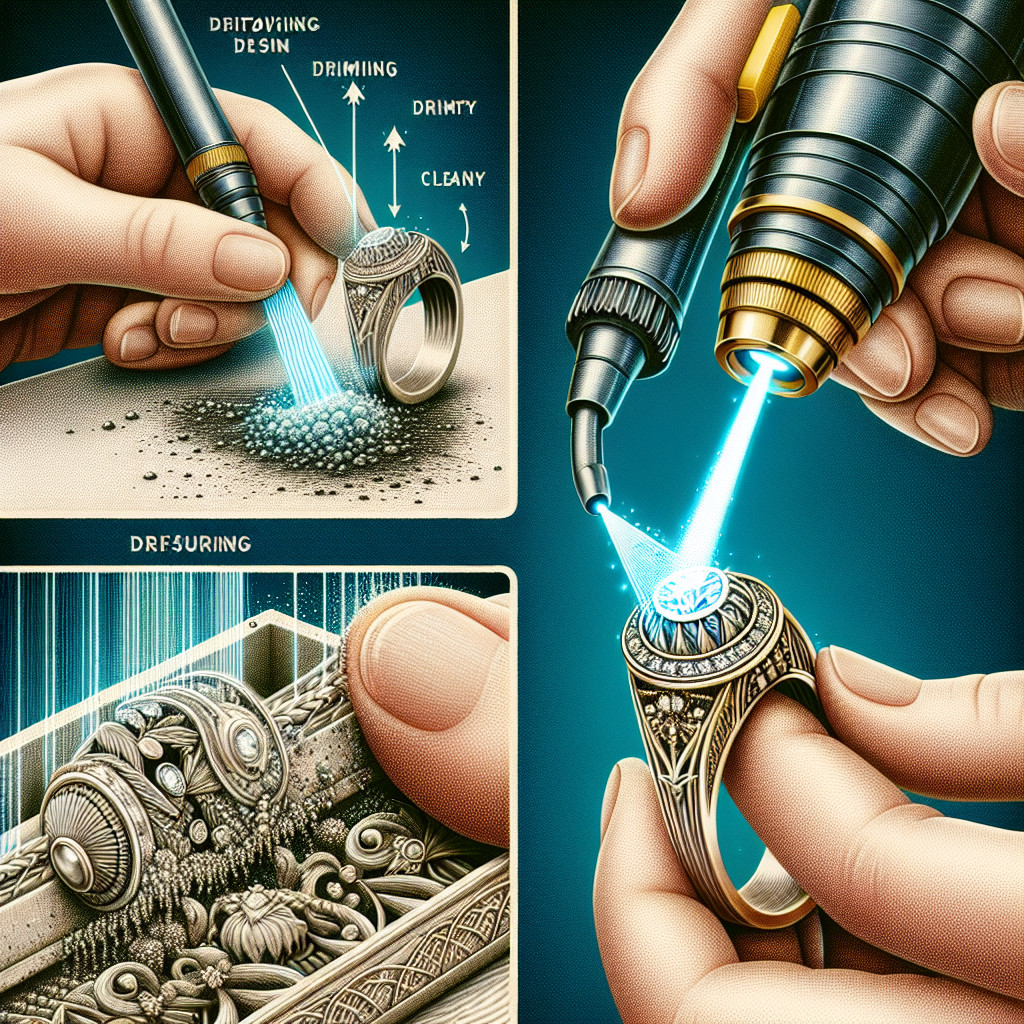

Laser cleaning works by using a focused beam of light to remove dirt, grime, and other impurities from the surface of the gemstone. The laser beam is directed at the surface of the stone, where it heats up and vaporizes the contaminants. This process is highly precise and controlled, allowing for targeted cleaning without affecting the integrity of the gemstone.

There are several benefits to using laser cleaning for gemstone restoration. One of the main advantages is that it is a non-contact cleaning method, meaning that there is no physical contact between the cleaning tool and the gemstone. This reduces the risk of damage to the stone and ensures that the cleaning process is gentle and safe.

Another benefit of laser cleaning is that it is highly effective at removing even the most stubborn stains and impurities from the surface of the gemstone. Traditional cleaning methods may not be able to achieve the same level of cleanliness and restoration that laser cleaning can provide.

Laser cleaning is being used in a variety of applications in gemstone restoration. It can be used to clean and restore a wide range of gemstones, including diamonds, rubies, sapphires, and emeralds. Laser cleaning is particularly effective at removing dirt, oil, and other contaminants from the surface of the stone, leaving it looking bright and shiny.

In addition to cleaning, laser technology can also be used to repair minor damage to gemstones, such as scratches or chips. The precision of the laser beam allows for targeted repair work that can restore the gemstone to its original condition.

Laser cleaning is a highly effective and safe method for cleaning and restoring gemstones. Its non-contact nature and precision make it an ideal choice for delicate gemstones that require gentle treatment. With the use of laser cleaning, gemstone owners can enjoy their precious stones looking as good as new.

#gemstones #laser cleaning #restoration #jewelry #precious stones #cleaning method #non-contact cleaning #targeted cleaning #gemstone restoration #diamonds #rubies #sapphires #emeralds #repair work #precision #delicate gemstones #gentle treatment.

In conclusion, the market for laser cleaning services for jewelry is growing rapidly, with plenty of opportunities for expansion and innovation. By staying ahead of the trends and investing in technology, companies in this industry can position themselves for long-term success.

#jewelry #laser #cleaning #services #market #analysis

frazy kluczowe:

– laser cleaning services for jewelry market trends

– opportunities for growth in laser cleaning services

– jewelry industry laser cleaning technology advancements

– personalized jewelry laser cleaning services

– luxury watch cleaning with laser technology.

Laser cleaning, on the other hand, uses a focused beam of light to selectively remove the engraved material from the surface of the jewelry. The laser energy is absorbed by the material, causing it to vaporize and be removed without affecting the surrounding area.

This process is highly controlled and can be adjusted to suit the specific requirements of each piece of jewelry. The laser can be programmed to remove only the engraving, leaving the rest of the surface untouched.

One of the key advantages of laser cleaning is its ability to remove engraving from a variety of materials, including precious metals like gold and silver, as well as gemstones and other delicate materials.

Furthermore, laser cleaning is a fast and efficient process that can be completed in a fraction of the time required by traditional methods. This makes it an ideal choice for jewelry restoration projects where time is of the essence.

In conclusion, laser cleaning plays a crucial role in removing engraving from jewelry by offering a precise, efficient, and non-destructive method for restoring the original appearance of pieces. Its versatility and speed make it a valuable tool for jewelry restoration professionals.

#laser #cleaning #engraving #jewelry #restoration #precise #technique #non-contact #delicate #metals #gemstones #fast #efficient #process

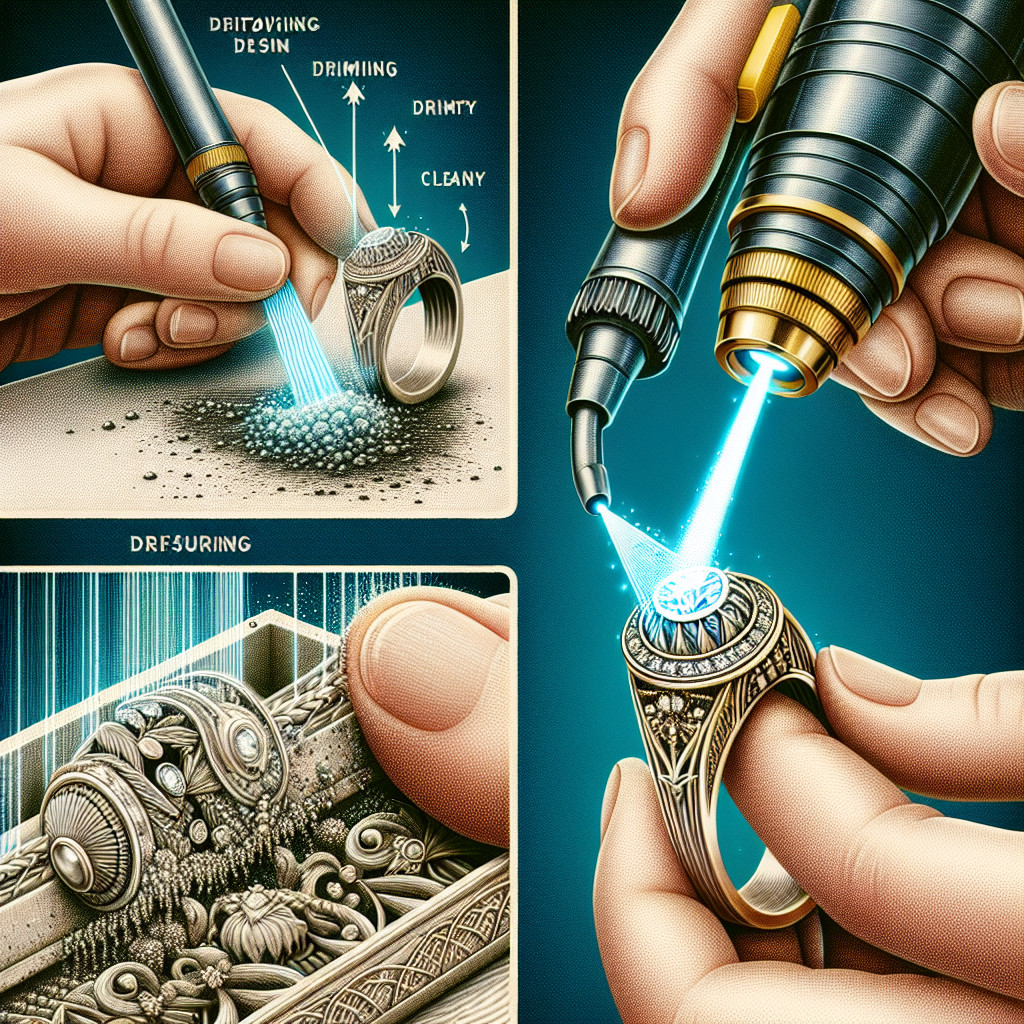

Laser cleaning is a non-contact, non-abrasive cleaning method that uses a high-energy laser beam to remove contaminants from the surface of an object. The laser beam is directed at the surface of the jewelry, where it vaporizes the contaminants without damaging the underlying material. This makes laser cleaning ideal for cleaning filigree jewelry, as it can effectively remove dirt, grime, and tarnish without causing any damage to the delicate designs.

Some of the key benefits of using laser cleaning to clean filigree jewelry include:

– Precision: Laser cleaning allows for precise control over the cleaning process, ensuring that only the contaminants are removed without affecting the underlying material.

– Gentleness: Laser cleaning is a gentle cleaning method that does not require any harsh chemicals or abrasive materials, making it safe for use on delicate filigree jewelry.

– Efficiency: Laser cleaning is a fast and efficient cleaning method that can quickly remove contaminants from the surface of the jewelry, saving time and effort.

Some of the include:

– Removing tarnish: Laser cleaning can effectively remove tarnish from filigree jewelry, restoring its shine and luster.

– Cleaning intricate designs: Laser cleaning can reach into the smallest crevices and intricate designs of filigree jewelry, ensuring a thorough cleaning.

– Restoring antique jewelry: Laser cleaning can gently remove dirt and grime from antique filigree jewelry, preserving its original beauty.

Overall, laser cleaning is a versatile and effective cleaning method that can be used to clean filigree jewelry safely and efficiently. By using laser cleaning, jewelry enthusiasts can ensure that their filigree pieces remain in pristine condition for years to come.

#laser #cleaning #filigree #jewelry

Keywords: laser cleaning, filigree jewelry, intricate designs, delicate details, gentle cleaning method

Long-tail phrases: non-contact cleaning method, intricate filigree designs, delicate filigree jewelry cleaning.